Real-Time Shop Floor Utilization, Downtime and OEE at Your Fingertips

Automatically monitor machines to increase profits and productivity and decrease downtime and waste.

Minitab Acquires Scytec to Power Real-Time Data Collection & Operational Excellence in Manufacturing

Solutions

- Modern, Real-Time Machine Monitoring

- Machine Monitoring

- OEE Monitoring

- Machine Downtime Tracking

- Shop Floor Data Entry

Modern, Real-Time Machine Monitoring

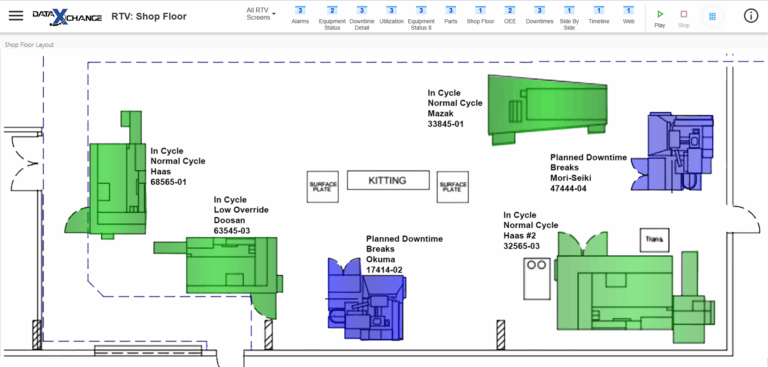

Configurable real-time manufacturing dashboards monitor machines and provide key performance indicators.

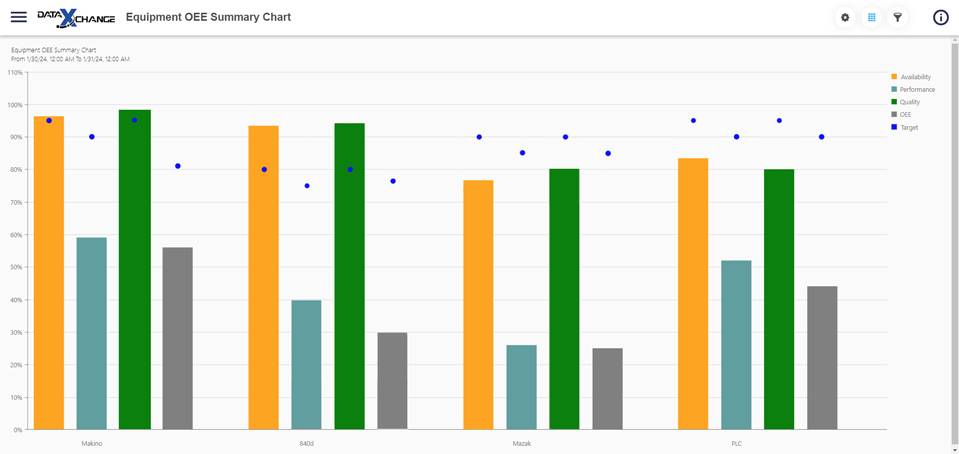

Machine Monitoring

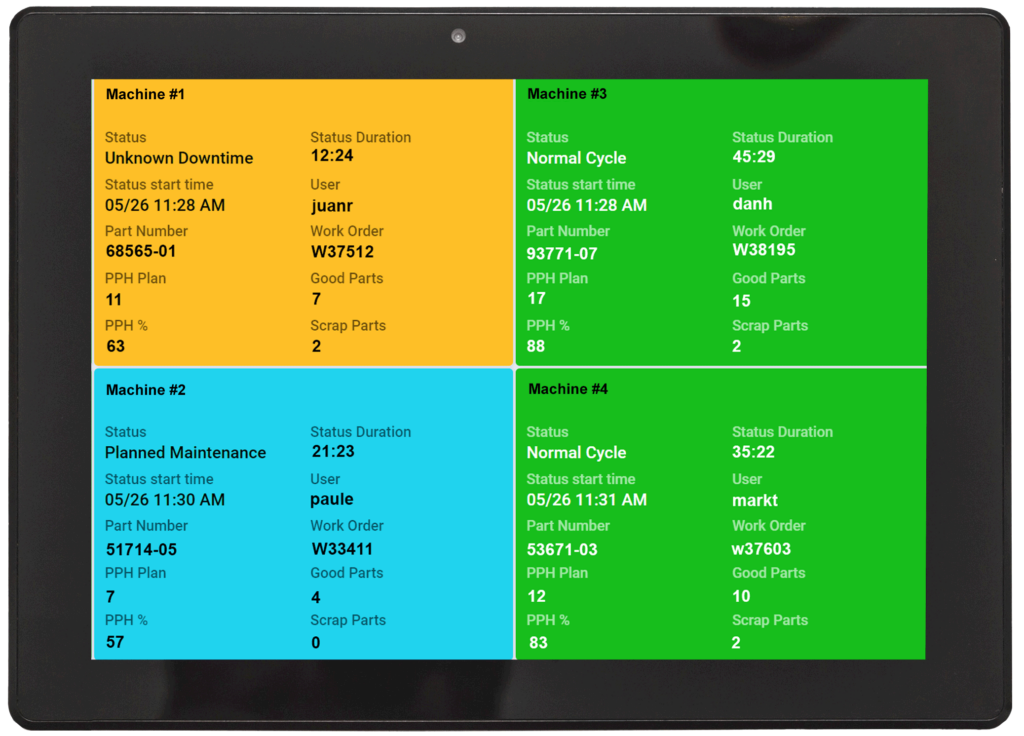

With an unlimited amount of screens available, views on the screen can show the current status of the equipment, part counts, target utilization, OEE metrics, downtime Paretos, downtime summaries, timeline views, shop floor layouts, Caron TMAC status, and much more. Additionally, each view can be configured to display the data in multiple ways, so you see the metrics exactly as you need them.

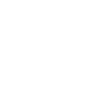

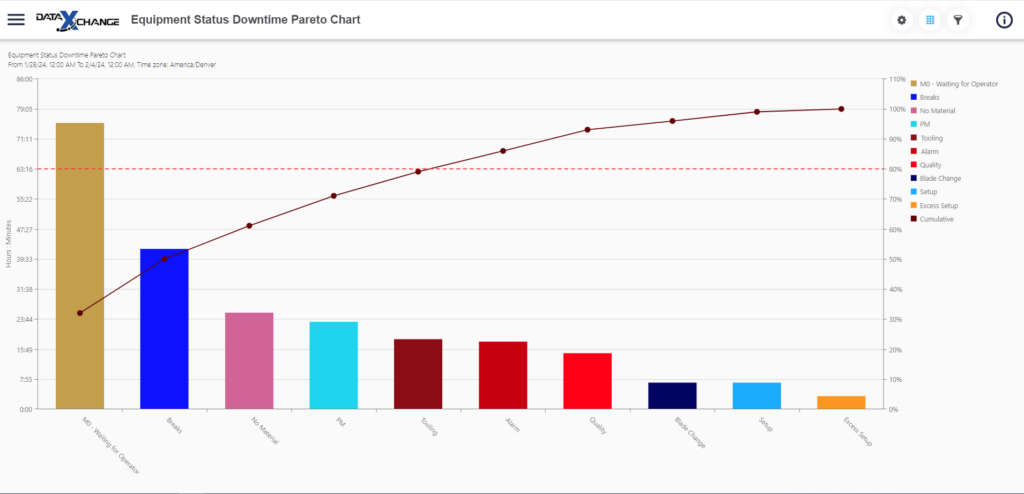

OEE Monitoring

DataXchange OEE software uses real-time equipment monitoring as well as automatic and manual collection of planned and unplanned downtimes to improve asset utilization. The DataXchange OEE software provides machine downtime tracking allowing for the identification of the waste, while automatic tracking of the machine activities allows for capturing the run rate.

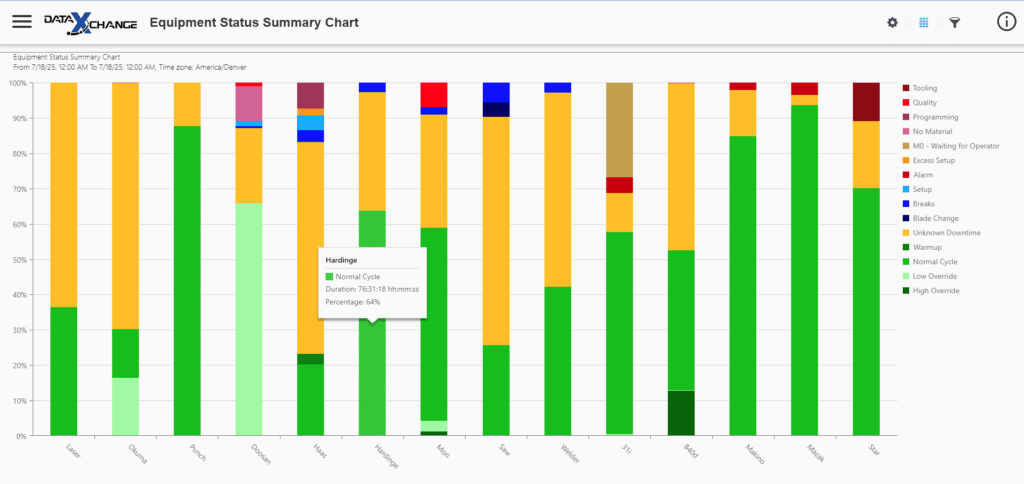

Machine Downtime Tracking

DataXchange offers a variety of machine downtime tracking methods to track both planned and unplanned machine downtime. Some downtimes can be pulled automatically from the equipment, and scheduled planned downtimes such as lunch breaks can be entered automatically with shop floor data entry rules.

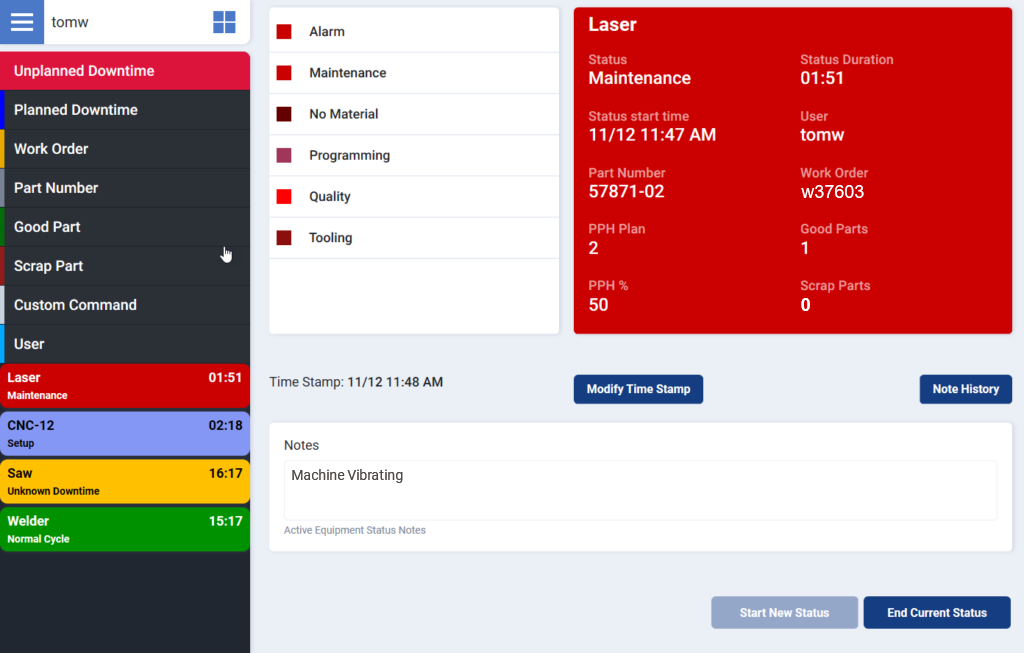

Shop Floor Data Entry

DataXchange offers an Operator Data Interface (ODI) that integrates with automatic machine data collection and allows shop floor personnel to enter information relating to planned and unplanned downtime reasons, work orders and operations, part counts, and much more.

Learn how to turn OEE data into real improvements by combining

Scytec DataXchange with Minitab Statistical Software

to uncover bottlenecks, root causes, and throughput gains.

Not sure what solution best suits you?

Flexible real-time machine monitoring for all levels

Fast to establish

- Collect data automatically using standard protocols such as MTConnect, OPC UA, Modbus TCP, and directly using proprietary protocols from controls like FANUC, Haas, Heidenhain, Mazak, OKUMA, Siemens, and more.

Easy to use

- Standardize OEE data across sites, equipment, and teams

- Operator Data Interface allows input from operators to categorize planned and unplanned downtimes, part count tracking, as well as triggering and sending email and text notifications to keep everyone updated on the status of the machines.

Flexible deployment

- Only vendor to offer cloud and on-premise deployment to meet your organization’s needs.

Discover how DataXchange can improve your operations.